Many fire doors are out of compliance. Here’s how to meet regulations.

The National Fire Protection Association standard, NFPA 80 2019, regulates the installation and maintenance of fire doors used to prevent the spread of fire and smoke within, into, or out of buildings. This latest edition continues to mandate annual inspections to meet local building, fire or life safety codes. NFPA 80 compliance is required for accreditation by The Joint Commission and Centers for Medicare & Medicaid Services (CMS) and to receive Medicare reimbursement. Many insurance companies also require NFPA 80 compliance before they underwrite commercial buildings.

The National Fire Protection Association standard, NFPA 80 2019, regulates the installation and maintenance of fire doors used to prevent the spread of fire and smoke within, into, or out of buildings. This latest edition continues to mandate annual inspections to meet local building, fire or life safety codes. NFPA 80 compliance is required for accreditation by The Joint Commission and Centers for Medicare & Medicaid Services (CMS) and to receive Medicare reimbursement. Many insurance companies also require NFPA 80 compliance before they underwrite commercial buildings.

MYTH: Fire doors that close and latch shut are compliant.

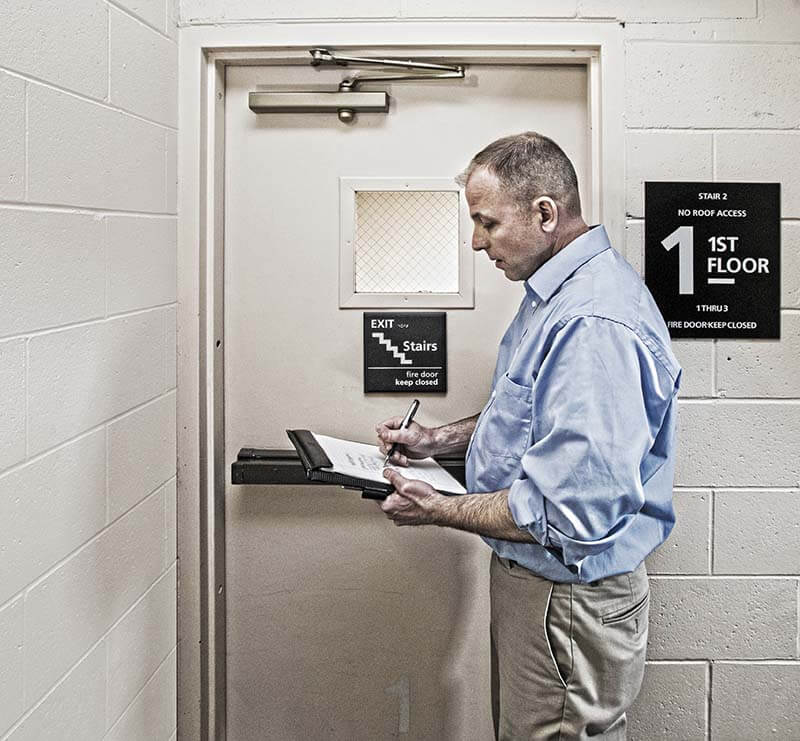

Many building owners and maintenance crews believe their doors will pass inspection if they close and latch shut. Not necessarily true. Here’s your checklist before an inspector comes:

- Look for holes or breaks on the door surface or frame and repair them.

- If the door is so equipped, inspect glazing, vision light frames and glazing beads. Make sure they are intact.

- Check that the door, frame, hinges, hardware and non-combustible threshold are secure, aligned and in working order.

- Inspect for missing, defective or broken parts and fix. Common red flags during inspections are latch bolts, and/or strike plates, closer arms and cover plates.

- With the door closed, measure clearances around the perimeter of the door and make sure they do not exceed clearances listed in NFPA 80 2019: 4.8.4 and 6.3.1. Make adjustments.

- Open the door fully and confirm that the self-closing device completely closes and latches the door. Adjust the device to get full closure.

- If a coordinator is installed, confirm that the inactive leaf closes before the active leaf. It’s not uncommon for maintenance departments to stock only active doors and to pair two active doors together which can create an out-of-compliance gap. You can often solve the problem by replacing the second active door with an inactive door. But a less costly solution is to install a concealed mount geared continuous hinge (recommendations below).

- Look for and remove auxiliary hardware items or objects that interfere or prohibit fire door operation or closure.

- Inspect for field modifications to the door assembly that void the fire door label.

- Verify the presence and integrity of any required meeting edge protection, smoke gasket and edge seats.

- Confirm that signage affixed to the door is attached with adhesive; screws are never allowed. Signage cannot exceed five percent of the door surface.

- Don’t be quick to blame the entire fire door for non-compliance. Before replacing it, consider replacing the hinges. According to fire inspectors, many of the non-compliant fire doors have clearance issues or unused fastener holes. Some doors are so out of alignment and the gaps so large that maintenance staff often thinks it must start over with a new door. It’s typically not a door problem, but a hinge problem.

Many fire doors are installed with butt hinges. What seems like cost savings at the time of construction does not always prove to be a money-saver over the life-cycle of the opening. Swing-clear butt hinges, used frequently in health care facilities, are rarely robust enough to handle heavy, high-traffic areas.

FACT: Install a SELECT hinge before the inspector comes. Your door will be compliant for decades.

Whether you are building a new facility or trying to eliminate out-of-code problems with existing doors, geared continuous hinges are often the best solution. But not all geared continuous hinges are engineered to last.

SELECT hinges are proven to withstand a 25-million cycle test and are backed with the industry’s only Continuous Warranty™. For a minimum of 60 years, you can expect minimal variance and gaps between the doors and frames. Barring other types of damage or missing parts, the door is likely to maintain the clearances it had when it was installed and pass inspections for decades.

For existing doors and fire doors, retrofitting with SELECT SL57, SL11 or SL21 is a viable solution. The SL57 full surface mount geared continuous hinge lets you manipulate out-of-alignment doors back into compliance while maintaining the integrity of the labeled openings. The SL11 concealed mount geared continuous hinge fills in gaps on excessively undersized doors, especially on pairs of doors. It allows you to move a door over as much as a one-quarter inch.

Swing-clear butt hinges on heavy, high-traffic fire doors are highly susceptible to bending. Replace with an SL21 full surface geared continuous hinge and you correct gap problems for good.

SELECT hinges are rated 90 minutes out of the box. If 3-hour geared continuous hinges are required, SELECT hinges can withstand those extreme conditions without a fire pin.