The standard for fire door safety

NFPA 80 2016 Standard for Fire Doors and Other Openings Protectives is the most current national standard. This latest edition continues to mandate annual inspections to meet local building, fire or life safety codes. NFPA 80 compliance is required for accreditation by The Joint Commission and Centers for Medicare & Medicaid Services (CMS) and to receive Medicare reimbursement. Many insurance companies also require NFPA 80 compliance before they underwrite commercial buildings.

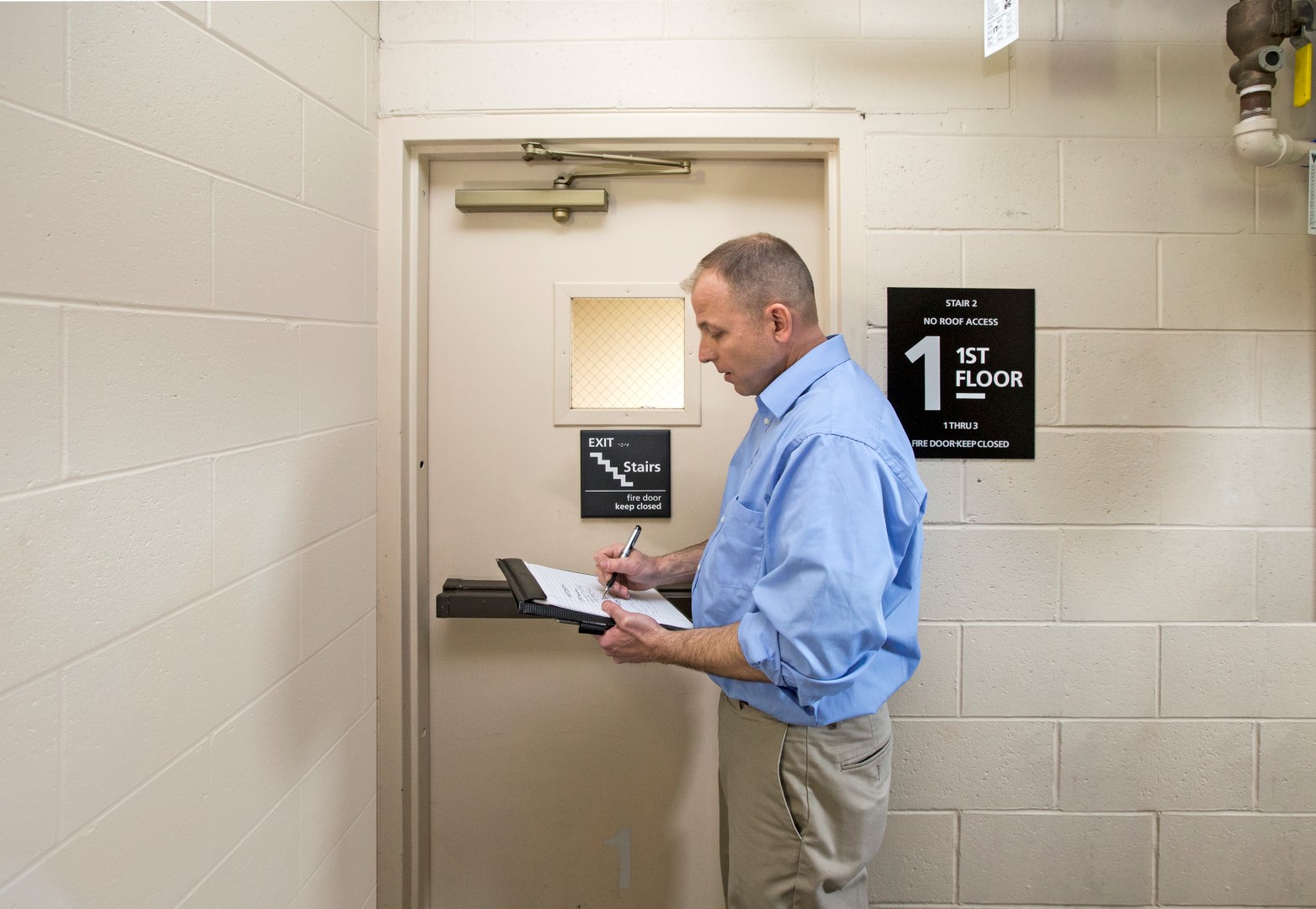

After years of inspecting fire doors, most are out of compliance

Building owners and maintenance crews often consider a fire door compliant if it simply closes and latches shut. But a latched door is not always fire code compliant. Upon inspection, these doors often don’t meet NFPA 80 standard requirements. Based on recommendations from the Door Security & Safety Foundation and many years of bringing buildings back into compliance, here are 14 tips to help get fire doors within code compliance before an annual inspection.

- Check door leaf and frames for fire door labels. Make sure the labels are legible. The door leaf label should be attached to the hinge edge of the door just below the top hinge or at the top edge of the door. A second label should be on the frame. Take time to read the labels and note whether they require installation of fire exit hardware on the door. If the labels are missing or painted over, the Authority Having Jurisdiction (AHJ) may require that they be replaced or inspected and re-certified by a credentialed laboratory.

- Look for holes or breaks on the door surface or frame. Check for rust-through on hollow metal frames. Look for holes from missing, removed or incorrect fasteners. On wood doors, check for split stiles caused by not using pilot holes to install fasteners. NFPA 80 does allow for repairs to be made in the field utilizing like material or steel. Each listing agency may also offer allowable repairs in the field without requiring re-certification. They should be contacted on a case-by-case basis.

- If the door is so equipped, inspect glazing, vision light frames and glazing beads. Make sure they are intact and securely fastened in place. Tighten loose and replace missing fasteners. Ensure that all glazing is properly labeled for the fire resistance of the opening.

- Check that the door, frame, hinges, hardware and non-combustible threshold are secure, aligned and are in working order. Verify that the face of the door is flush or slightly inset with the face of the frame. Check that the top and bottom flush bolts project one-half inch into the strike. Look for signs of damage. Be aware that it is not uncommon for cleaning crews to brace open a door with a mop handle or other object and damage the frame, hinges or hardware. Realign or repair damage.

- Inspect for missing, defective or broken parts. Common red flags during inspections are latch bolts, and/or strike plates, closer arms and cover plates. Replace with new OEM parts or replace with exact templated equivalents.

- With the door closed, measure clearances around the perimeter of the door. On paired doors, without overlapping astragals, measure between the meeting stiles. Look for wear on the frame or the paired door leaf. Wear often indicates misalignment or poor clearance. See NFPA 80 2016 for clearance requirements. Adjust the door to bring it back into compliance.

- Open the door fully and confirm that the self-closing device completely closes and latches the door. Adjust the self-closing device to achieve full closure and latching without exceeding 15 lbs. of opening force pressure.

- If a coordinator is installed, confirm that inactive and active leaves operate in correct sequence. Open the door, then close it, observing whether the inactive leaf closes before the active leaf. It’s not uncommon for maintenance departments to stock only active doors and to pair two active doors together. This can create an out-of-compliance gap. The problem can often be solved by replacing the second active door with an inactive door. However, a less costly solution for eliminating the excessive gap is to install a geared continuous hinge, concealed mount (recommendations below).

- Check latching hardware operation. Make sure that the latch secures the door in the closed position. If the door is not securely latching, evaluate whether it is a faulty latch or door misalignment. A potential solution would be to replace the hinge (information below).

- Look for auxiliary hardware items or objects that interfere or prohibit fire door operation or closure. Ensure that plant-ons and overlays do not cause the face of the door to extend beyond the face of the frame. Uninstall interfering auxiliary hardware items from the door or frame. Remove any items bracing the fire door open including furniture, boxes and/or equipment.

- Inspect for field modifications to the door assembly that void the fire door label. Look for barrel bolts, dead bolts or kick down door holders. Remove non-compliant plant-ons.

- Verify the presence and integrity of any required meeting edge protection, smoke gasketing and edge seats. Verify the top edge of the kick plate is not more than 16 inches from the bottom of the door. (Protection plates mounted higher than 16 inches from the bottom of the door are required to be labeled.) Check that the smoke gasketing forms an unbroken, lightproof seal along the vertical lines and top edges of the door. This smoke gasketing cannot interfere with closing the door. Replace or repair as needed.

- Confirm that signage affixed to the door is attached with adhesive; screws are never allowed. Signage cannot exceed five percent of the door surface.

- Don’t be quick to blame the entire fire door for non-compliance. Before replacing it, consider replacing the hinges. Many of the non-compliant fire doors I and other fire door inspectors observe in the field have clearance issues or unused fastener holes. Some doors are so out of alignment and the gaps so gargantuan that maintenance staff often thinks it must start over with a new door. I often point out during my inspections that it’s not the door, but the hinge that is causing the problem.

Many fire doors are installed with butt hinges. What seems like a cost savings at the time of construction design does not always prove to be a money-saver over the life-cycle of that opening. Swing-clear butt hinges, used frequently in health care facilities, aren’t usually robust enough to handle heavy, high traffic areas. This type of door hinge is very susceptible to bending. In fact, I’ve gone into hospitals and found one-third of the newly installed fire doors with swing-clear butt hinges out of compliance within a month.

What I usually recommend is (a) from the start, install a geared continuous hinge on fire doors or (b) use a geared continuous hinge to retrofit an existing problem fire door. There are multiple manufacturers of geared continuous hinges, but from my experience building owners don’t want to keep reinvesting in them. I recommend SELECT hinges, in part because of their Continuous Warranty™ and 25-million cycle test. With these hinges, you can expect minimal variance and gaps between the doors and frames for a minimum of 60 years. Barring other types of damage or missing parts, the door is likely to maintain the clearances it had when it was installed and pass inspections for decades.

For existing doors and fire doors, retrofitting is a viable solution. Most of the clients I see are happy when they replace their hinges with SELECT SL57 geared continuous hinges, full surface mount. These hinges let them manipulate their doors back into compliance while maintaining the integrity of the labeled openings. The SL11 geared continuous hinge, concealed mount, fills in gaps on excessively undersized doors, especially on pairs of doors. It allows you to move a door over as much as a one-quarter inch.

While swing-clear butt hinges on heavy, high-traffic fire doors are highly susceptible to bending, an SL21 geared full surface hinge can correct the problem for good.

No matter what hinge is installed on fire doors, it’s critical that it meets the requirements of the fire listing. SELECT hinges are rated 90 minutes out of the box. If 3-hour geared continuous hinges are required, I encourage hardware specifiers to look at the various geared continuous hinge manufacturers’ designs. Most require the use of fire pins that will add to the installation time. SELECT does not require a fire pin to hold its hinges in place under these extreme conditions.

Now that building owners know that annual NFPA 80 inspections are required for fire doors, following these 14 tips will make staying in compliance easier. But keep in mind, the solution for many of the problems you’ll see may be as simple as installing the right hinges. Do so before the inspector comes.

Hal Kelton is a certified fire and egress door inspector and owner of Kelton Sales Group, LLC in Monterey, CA. For 30 years, he’s helped owners and facility managers of Californian office buildings, residence halls, military and health care facilities evaluate their sites for fire and egress door code compliance.